إدارة مستودعات الأدوية

نظـــــام تتبــــــع الأدويـــــــة للمنتجــــــات الصيدلانيــــــة

تماشياً مع نظام تتبع الأدوية للمنتجات الصيدلانية (RSD) الذي أنشأته الهيئة العامة للغذاء والدواء في السعودية ، كواحدة من خططها للمساهمة في تحقيق رؤية المملكة 2030 ، قامت شركة مرمرة بتطوير وبرمجة نظام (CNECT®) لتوفير جميع خدمات التسلسل والتجميع للأدوية لسلسة التوريد عبر جميع مرافقها. يوفر نظام CNECT® حلولًا كاملة للتتبع من طرف إلى طرف لمكافحة الغش الدوائي في جميع أنحاء سلسلة التوريد من الشركة المصنعة إلى المستهلك ، مع أكثر من 10 سنوات من الخبرة ، CNECT® هي المزود الرئيسي لأنظمة التسلسل والتجميع المبتكر والذي بدوره يساعدك لتوفير حل موثوق للأعمال الخاصة بك.

نحن نساعد ...

الحكومات

حماية المجتمع وضمان سلامة الأدوية بمعرفة مصدرها ابتداء من مرحلة التصنيع حتى الوصول للمستهلك.

المصنعين

لمساعدة المصنعين في مشاركة البيانات المتسلسلة مع الجهات الرقابية والموزعين وموفري الطرف الثالث وتجار التجزئة ، والعمل على ضمان وصول الجميع إلى المعلومات.

الموزعين

لتحقيق عدد من الفوائد ، بما في ذلك تحسين إدارة المستودعات ، وزيادة الإنتاجية ، وتقليل أعمال إدخال البيانات ، ومؤشرات الأداء الرئيسية للعمالة ، وتتبع كل وحدة عمل على أساس يومي ، والتعامل مع المنتجات التالفة والمزيد.

الموردين

للحفاظ على العمر الافتراضي للأدوية قدر الإمكان من خلال إجراء التسلسل والتجميع بطريقة بسيطة وسريعة واستغلال مساحة أقل في المستودع أثناء التشغيل.

الصيدليات

لتسهيل المبيعات وتتبع العمل في الصيدلية ، قمنا بتطوير نظام نقاط البيع المتصل والمتوافق مع نظامCNECT® ، حتى تتمكن الصيدلية من إجراء عمليات البيع والتتبع بكل سهولة ويسر وبما يتوافق مع الأنظمة.

المستهلك

لحماية المستهلك من عمليات الغش الدوائي، أتاحت عمليات التسلسل والتجميع لأي مستهلك مسح الرمز الموجود على أي عبوة دوائية للاستعلام عن جميع التفاصيل التي تم جمعها.

لدينا الحلول للمشاكل

"ما يميز نظام ®CNECT هو تعامله مع الأدوية في جميع ظروف التخزين"

تواجه أنظمة التسلسل والتجميع الأخرى صعوبة في التعامل مع الأدوية المخزنة في ظروف خاصة، مثل الثلاجة أو الفريزر أو ظروف تخزين أخرى. الآن، بفضل نظامCNECT® ، يمكنك مسح الأدوية باستخدام ماسح ضوئي محمول وهي في مكانها ودون تغيير مكان التخزين. نحن لا نقوم بتحريك الأدوية من مكانها. نحن فقط نقوم بمسح الأدوية ونغلق الباب.

نقوم بزيادة الإنتاجية

"توفير الوقت والموارد عند التعامل مع كميات كبيرة من المنتجات"

عند استخدام حلول أخرى غير CNECT® سيكون لديك مصدر واحد لإنجاز هذه المهمة ربما لآلاف العبوات عند استخدام الجهاز الثابت للتعامل مع إجراءات التسلسل والتجميع. يمكنك تخيل الوقت الذي تقضيه للقيام بهذه المهمة. بدلاً من ذلك ، باستخدام نظام CNECT® ، يمكنك توزيع الماسحات الضوئية المحمولة على العديد من العمال داخل المستودع ، وسيكمل كل منهم الإجراء الخاص بمجموعة محددة من العبوات.

لا مزيد من المساحات في المستودع بعد اليوم

لتنفيذ إجراءات التسلسل والتجميع ، يغنيك نظام CNECT® من الحاجة إلى المعدات والآلات الكبيرة التي تأخذ مساحات كبيرة. عند استخدام حلول أخرى ، ستحتاج إلى مساحة تصل إلى 100 متر مربع لإكمال عمليات التسلسل والتجميع. باستخدام نظام CNECT® ، ستحتاج فقط إلى 2 متر مربع لإتمام الأعمال.

نقوم بمعالجة النقص والعبوات التالفة

يحدث النقص في العبوات عادة بسبب أخذ عينات من الجهات الرقابية للفحص أو لأسباب أخرى أو بسبب أخطاء في التعبئة، لذلك تقوم الأنظمة الأخرى بتعويض النقص من صندوق آخر ولا يتم معالجة هذه المشكلة. عند استخدام نظامCNECT® ، يمكنك التعامل مع النقص أو التلف بطريقة احترافية عن طريق إجراء استدعاءات آلية بين العمال والمشرف، ويحدد المشرف نوع النقص أو التلف، والنظام يقوم بإعطاء أوامر لطباعة الملصق الذي يوضح النقص، ثم يتم طباعة تقرير الحادث والموافقة عليه وتعميده من قبل المشرف والمسؤول والإدارة العليا. نفخر من خلال نظام CNECT® بتوفير هذه الخدمة، ولا توجد أنظمة أخرى تقدم خدمة سجلات التدقيق.

نقوم بمعالجة عمليات التعويض

يتميز نظام CNECT® عن الأنظمة الأخرى بتوفر ميزة التعويض التي تساهم في تقليل عدد الصناديق التي تحتوي على نقص أو تلف في المنتجات تلقائيًا من خلال التبادل التعويضي بين الصناديق ويتم معالجتها داخل النظام بطريقة احترافية.

نقوم بتقليل التكاليف

عند استخدام أنظمة أخرى ، يتطلب إجراء التسلسل والتجميع ثلاثة عمال في المستودع ، وهناك تأخير بين العمليات. أحد العمال يقوم بعمليات التسلسل والآخر ينتظر أن ينتهي الأول حتلا يبدأ عملية التجميع ، وهناك العامل الثالث ينتظر لترتيب الصناديق على الطبلية وإلصاق الملصق الخاص بها. "يمكنك تخيل مقدار الوقت والمال الضائع بهذه الطريقة" باستخدام نظامCNECT® ، تتم معالجة عمليات التسلسل والتجميع مرة واحدة خلال مرحلة واحدة من العمل وتحتاج إلى عامل واحد فقط لإنجاز هذا العمل.

نقدم مستويات معددة من عمليات التحقق

يتميز نظامCNECT® عن الأنظمة الأخرى من خلال توفر ميزة التحقق متعددة المستويات ، حيث يقوم المشرف في المستوى الثاني من التعميد ، وكذلك المسؤول في المستوى الثالث من التعميد ، بتفويض عمليات التجميع قبل إغلاق الصندوق .

مرحلة واحدة من العمل وليس مرحلتين

يقوم نظام CNECT®من إجراء عمليات التسلسل والتجميع في نفس الوقت من خلال مرحلة واحدة

عند استخدام نظامCNECT® ، ستتمكن من إجراء مهام التسلسل والتجميع في نفس الوقت. طابعتان متصلتان بالنظام. عند مسح أحد الملصقات ثنائية الأبعاد وإجراء مسح ضوئي لواحد من الباركودات ، سينهي النظام عملية التجميع تلقائيًا ، مما يلغي الحاجة إلى مسح جميع الرموز لاتمام عملية التجميع.

مميزات النظام

تم تطوير نظامCNECT® بطريقة تحقق مجموعة من المبادئ والعمليات التي يحركها النظام وخصائص التشغيل ودقة البيانات ومسارات تدقيق الجودة وتتبع الأداء والبساطة للحصول على أفضل تجربة للمستخدم ولتحقيق الأهداف التالية:

- نظام إرشادي: سيرشد المستخدمين لأداء مهامهم وفقًا للعملية المطلوبة.

- الجودة: يضمن النظام أن جميع الخطوات تتم بالتسلسل الصحيح.

- دقة البيانات: يحتوي النظام على خطوتين قبل التخزين النهائي للبيانات ، وجمع البيانات ، ثم تأكيد البيانات من قبل مستخدم مختلف.

- مستويات متعددة من التحقق: يتم تتبع كل إجراء على بشكل منفصل ، وتسجيل كل انحراف لأغراض الامتثال للجودة.

- تتبع الأداء: يوفر لوحة معلومات مباشرة لقياس الأداء والإنتاجية ، كما يتم توفير مجموعة واسعة من التقارير لتقديم صورة واضحة للعمليات.

- البساطة: توفر واجهة بسيطة وسهلة الاستخدام ، ولا يلزم الضغط على مفتاح أو النقر بالماوس ، وقد تم تصميم جميع الشاشات لتوفير المعلومات والتعليمات للمستخدم برؤية بسيطة وواضحة / إخطارات صوتية.

المكونات الأساسية

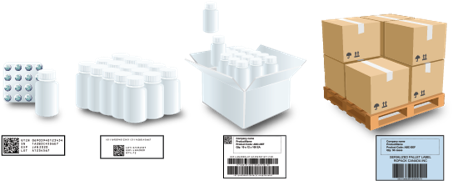

يعتمد نظامCNECT® على أربع وحدات ، تم تحسين كل منها لأداء مهام خاصة، في حين أن المجموعة التي تحدد عملية التجميع والتسلسل قوية جدًا وصلبة ودقيقة ، فإن ناتج هذه العملية سيسهل حركة البضائع الدقيقة والفعالة من حيث التكلفة بين جميع عمليات سلسلة التوريد.

جوهر النظام

يتحكم في العملية بأكملها ، وإدارة الاتصالات والرسائل بين الوحدات النمطية الأخرى ، والعمل ضمن مستوى تخزين البيانات.

مدير النظام

نظام مستقل يستخدمه مدير العمليات ، ينظم العملية بأكملها من خلال تحديد المهمة الحالية رقم GTIN ، وبدء / إنهاء ورديات العمل ، وتحديد مجموعات العمل (علاقة المشرفين / العمال) ، وإدارة حالات الانحراف وإنشاء تقارير التدقيق.

المشرف

وحدة تُستخدم لمراقبة مجموعة من المُجمِّعين ، وتنفيذ إجراء تأكيد لعمليات المُجمِّع وضمان إنتاجية المُجمِّعين.

المجمّع

تُستخدم هذه الوحدة لأداء مجموعة المسلسلات لكل وحدة على حدة ، والقراءة السريعة واستخراج البيانات لمصفوفة بيانات GS1 ، والعمليات التي يحركها النظام ، وواجهة مستخدم بسيطة للغاية.